EJECTOR COOLERS Division

Cooling in vacuum: Development of cooling techniques in vacuum is growing rapidly. Liquids, emulsions and suspensions cool by themselves without the use of other cooling liquids.

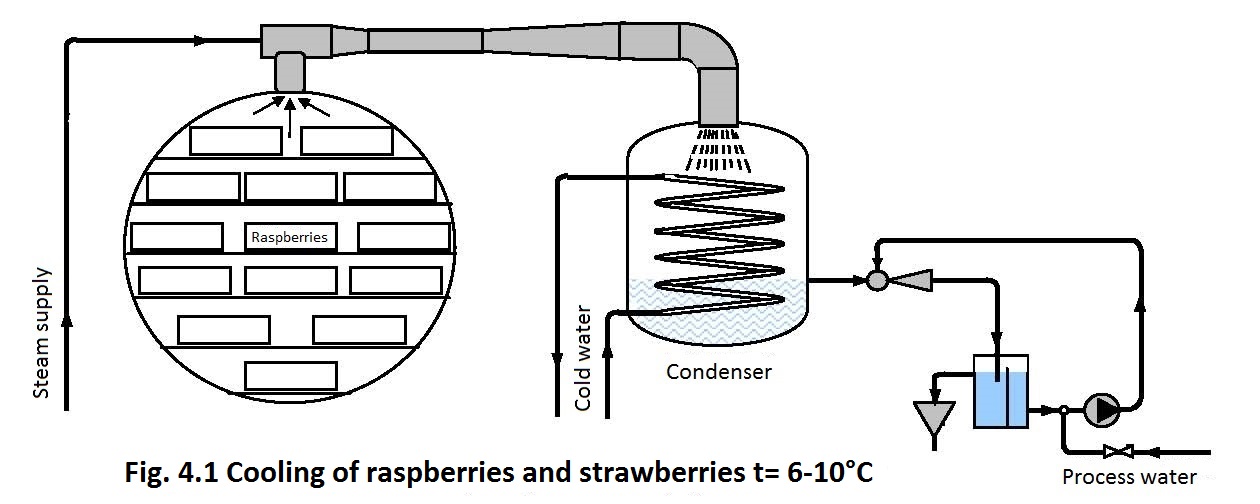

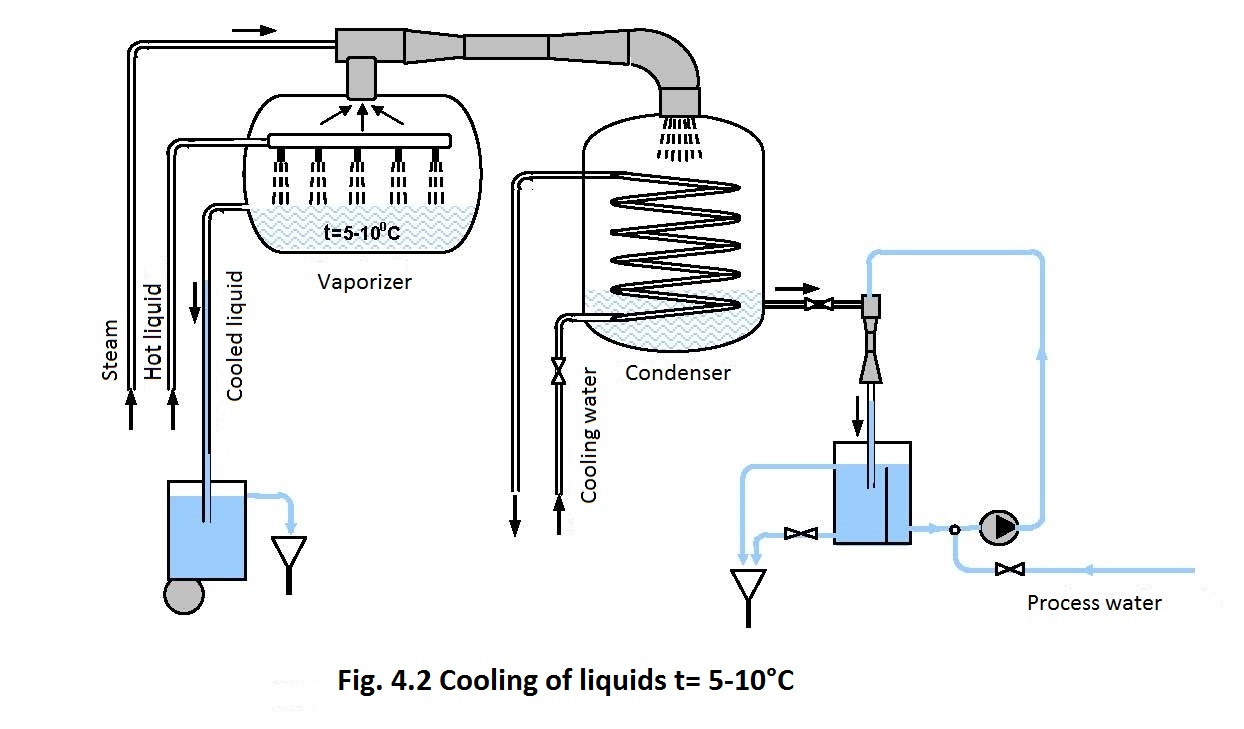

One of the methods of fast cooling in vacuum is using ejector cooling devices, i.e. ejector vacuum pumps (see Ejector vacuum pumps).

In ejector cooling devices vacuum is provided by ejectors using water or water vapor as the driving fluid. Water as the cooling fluid is used for cooling small areas, while water vapor is used for cooling small and large areas up to several hundred m3.

Operating principle:

Liquid in damp powder, dough-like and other materials when they are in areas where the absolute pressure is lower than their vapor strain start to boil and evaporate suddenly creating equilibrium state between the absolute pressure and temperature.

Part of the evaporating liquid takes the heat required for evaporation from the surrounding material and space and thus cools them.

Increasing vacuum increases the amount of evaporated liquid and reduces the temperature of the surrounding space and material being cooled. The evaporated liquid is pumped in by the ejector thus maintaining a set vacuum and corresponding equilibrium temperature.

Application:

Ejector cooling devices are used for cooling liquids, emulsions and suspensions, for cooling damp dough-like, powdery and other damp materials and materials that can be wetted before cooling, for cooling closed areas and maintenance of a set cooling temperature.

They are especially widely applied:

For initial cooling of berry fruits (raspberries and strawberries) before they are transported to coolers for final cooling. This procedure can be used for initial cooling large amounts of vegetables and fruit to a desired temperature. Cooled this way they can be transported to freezer facilities for further deep freezing. In the world such freezing systems are constructed for capacities up to 15000 tons a day.

With such cooling fruits are cooled and dried at the same time thus preventing formation of ice crusts around the fruits and fruit sticking together.

Vacuum cooling maintains a continual and instant equal temperature on the whole area and thus uniform cooling. This procedure enables great savings in heat transfer equipment (heat exchangers are not needed at all) in viscous solutions and highly corrosive solutions, such as phosphoric acid etc.

|

For many cooling processes a certain amount of solid particles separate and sediment when solution cooling takes place. If in these cases classical coolers are used then their internal surfaces soon become covered in sediment that reduces the cooling efficiency. In vacuum cooling, due to cooling along the whole depth layer, thickness of the sediment can be 2-3 cm, even more and cleaning occurs in very rare intervals.

Heat energy, taken from the cooling material can be utilized in other processes.

Advantages in relation to classical cooling devices are:

- equalized cooling temperature of the whole area;

- the cooling technology is completely clean, the surrounding area and material being cooled are not polluted as water or water vapor are used as the cooling fluid;

- the cooled material is dried as well. These cooling devices have a simple construction and small dimensions;

- they have no mobile parts so do not require maintenance and lubrication;

- their operation is stable, quiet with no noise and vibrations;

- they are mounted fast and easily in all positions, investments are small and lifetime limitless.

Material:

They can be made from all types of metal, plastic and other solid and hard materials.

|