About Ejectors General Information

EJECTORS (INJECTORS) OR JET PUMPS belong to the group of jet machines.

Compared with other pumps they have a series of advantages:

- simple construction,

- small mass and dimension,

- easy to handle and maintain,

- no mobile parts,

- do not require lubrication,

- easily mounted in all positions,

- do not require special bases,

- stable, quiet and noiseless operation,

- allow regime change in wide ranges,

- cheep,

- long lifetime.

One of their characteristics is that they do not require driving engines as they use the energy of input fluids for driving.

Based on the theory we developed, many experiments and great experience on many different types of installations optimization of current and geometric parameters was performed enabling operation with a high degree of utilization.

n = 0.25 – 0.75

Ejectors are widely applied in many fields. In the last few years several patents have been registered in the world and this country (our patents) that give new original solutions simplifying existing technological procedures.

Ejectors are suitable for automation with minimal occasional work control.

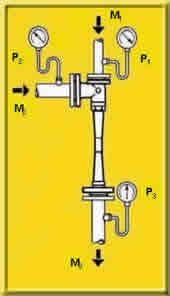

Ejectors consist of:

- jets with a driving fluid attachment,

- mixing chamber with an attachment for fluid intake,

- diffuser with an emptying attachment.

Principle of ejector operation: All types of ejectors, regardless of their purpose and size, operate on the same principle. For operation they use energy of the input fluid. Fluid with a higher input pressure is called a driving fluid, while fluid with a lower input pressure is pumped in. Several different fluids can be pumped in at the same time.

All fluids can be used as driving or pumped: liquids (emulsions, suspensions), gasses, vapor and all other materials that can become liquid. All combinations are possible.

Ejector construction was performed so that the fluid pumped in is taken in, compressed and then driven with the energy of the driving fluid.

Main ejector operations are:

- drive,

- pumping in and mixing,

- emptying.