EJECTOR HYDRO-TRANSPORT Division

Hydro-transport is transport of a hydro-mixture consisting of a liquid (most often water) and small undissolved particles.

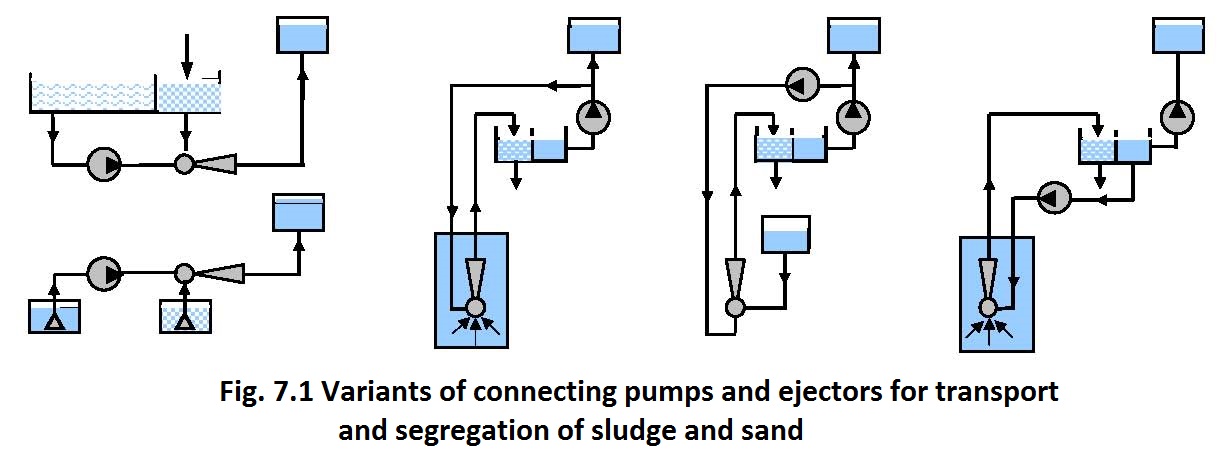

Besides other devices, ejectors are used for hydro-mixture transport. Ejectors can be used for transport of loose solid materials, whose particle size can be larger than 25 mm. They are used for flows up to several 100 m3/h, with exit pressures higher than 20 bar.

Operation principle:

Ejectors operate on the same principle as all other ejectors (see Ejector hydro-pumps)

Dosage:

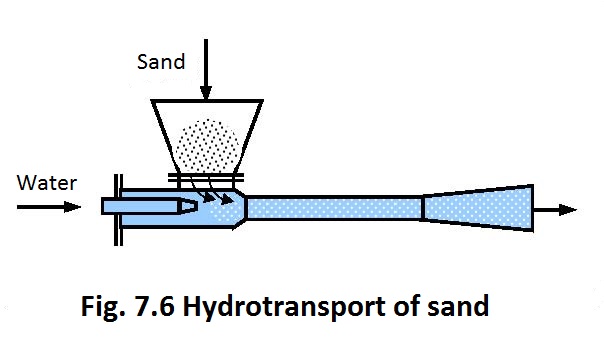

The pumped material can be a solid loose material with no liquid or in the form of a suspension. Most efficient transport is achieved when pumping pure loose material with no liquid. Dosage of the loose material with no liquid content can be free fall or with dosage devices.

Concentration of the output mixture:

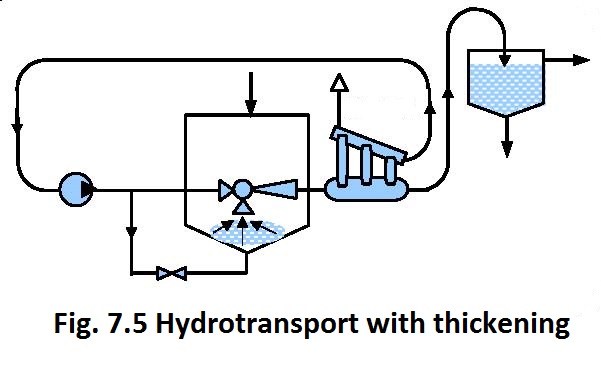

Concentration of the mixture exiting the ejector can be realized in a required ratio. The mass concentration of the mixture varies in a wide range and is most often adjusted to requirements of the transport pipeline. The mass concentration of the solid material in relation to water is up to 50% and it can be higher in some cases.

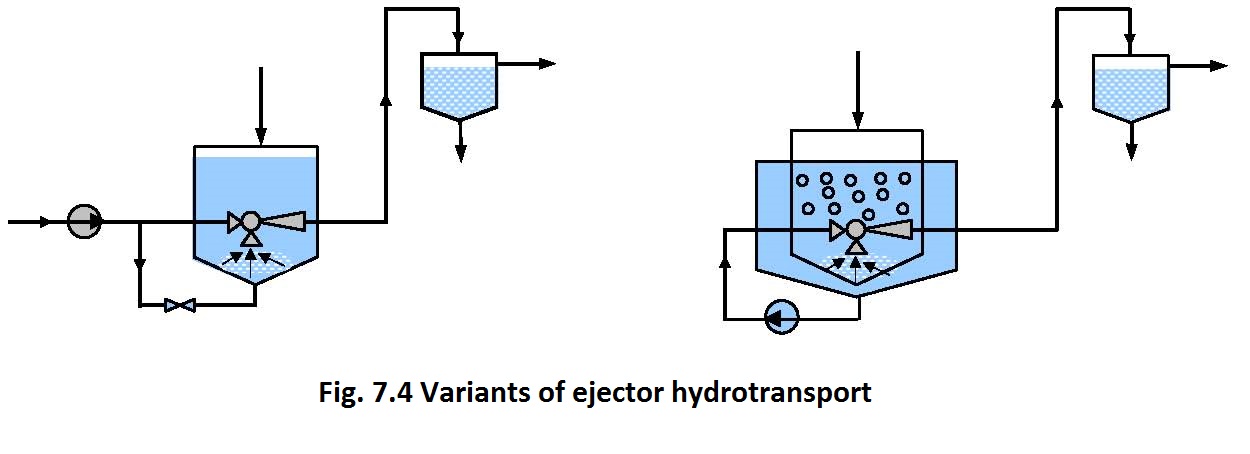

In classical constructions the volume of the driving liquid is 3-5 times higher than the volume of the transported material, though in some cases the volume concentration of the solid material can be as high as 49%.

Solid materials that can be poured are dosed into the ejector dry, while materials that have a tendency of building bridges and arches are dosed with certain amounts of water. Introduction of water into the dosage basket enables formation of a liquid suspension that enables even dosage and does not allow formation of bridges and arches before the ejector. If clean and solid material is taken in from the input basket without water then the ejector performs mixing as well as transport. Consumption of additional water for creation of a liquid input suspension depends on the type of material that needs to be transported and for granules with spherical surfaces and small dimensions up to 1.5 mm it is about 20% of the weight of the material to be transported.

In difficult conditions, when transporting coarse materials with rough surfaces and relatively high density with a tendency of formation of bridges and arches, such as, for example, ash, sand and sticky substances it is necessary to use 5-10 times larger amounts of water than the amount of material being transported. This amount includes additional water added to the solid material before entering the ejector. Introduction of liquid suspensions enables achievement of high output pressure of the ejector. The ratio between the input pressure of the driving water and the output pressure of the hydro-mixture is in the range 2.5-3.

Application:

They are used for internal and external transport, pumping and thrusting solid loose materials of different types, shapes and origin (sand, gravel, slag, ore, coal, mud, cattle beet etc.).

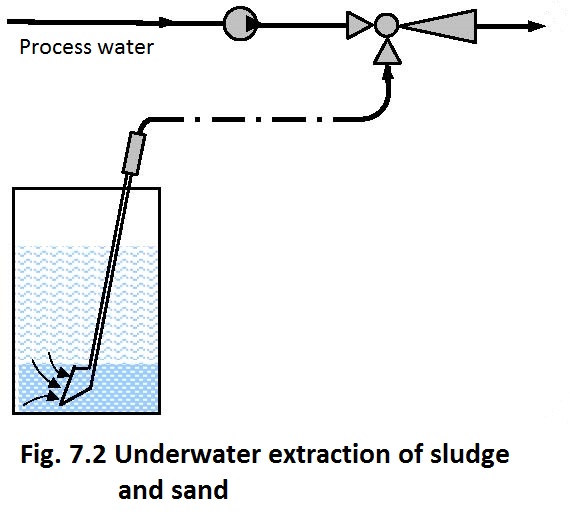

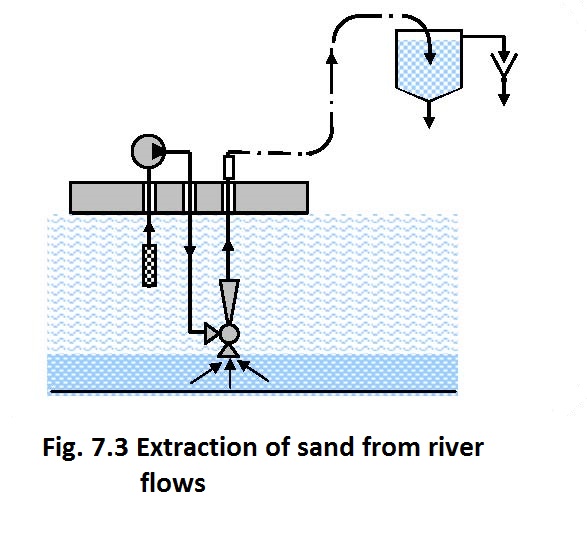

They are highly applied when cleaning pools, wells, manholes, mud piles in front of dams and sluices etc. Ejectors can be used to pump and thrust sandy, muddy and dirty liquids containing smaller or larger pieces of solid material from great depths (underwater). The complete cleaning process is performed underwater without removing the water. They are suitable for extracting gravel and sand from river beds and their transport into collecting basket.

Advantages:

They can be used for the transport of small and large pieces sized up to 25 mm, they have no driving engines so do not require electric energy, they have no mobile components so do not require lubrication and maintenance, they have a relatively small mass and dimensions, mounting and taking down is simple and easy and they can be installed in all positions, their operation is quiet and silent, purchasing price is low and lifetime is long.

Material:

Metals, non-metals and plastic are used for ejector construction. They are most often made from high density polyethylene with a large molecular mass exceptionally resistant to wear and abrasion.

|

| m2/m1 – kgsuctioned material/kgpumped water |

Example 7.1

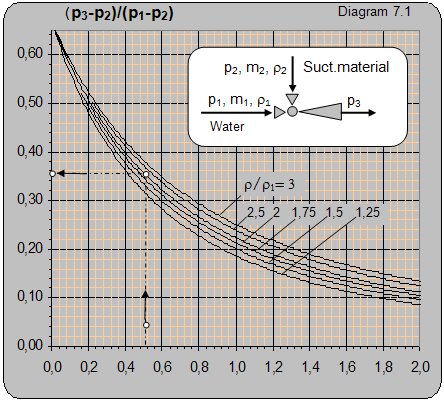

Data: From the dosage basket a suspension with pressure p2 = 1 barabs and density r2 = 2 kg/m3 is dosed into the ejector. The pressure at the ejector output is 3 barabs. The mixture formed by the ejector has the mass flow ratio of m2/m1 = 0.5.

The driving pressure p1 needs to be determined?

Solution: From diagram 7.1 one can for the mass flow ratio of m2/m1=0.5 read (p3-p2)/(p1-p2) = 0.358 from which

follows that p1 = 6.59 barabs = 5.59 bar.

(p3-p2)/( p1-p2) = 0,358, from this follows p1 = 6,59 baraps = 5,59 bar.