EJECTOR PUMPS Division

Ejector pumps are used for drawing-in (pumping), thrusting and transport of all types of liquids, emulsions and suspensions. Pumped and drawn-in liquids can contain gases (air, methane, carbon dioxide etc) and un-dissolved solid grains and pieces of material of different origin and size.

They are used for performing a series of different operations in many fields (industry, construction, waterpower engineering, mining etc.).

Depending on the type of driving fluid they are divided into:

- ejector hydro pumps (liquid-liquid)

- ejector gas pumps (gas-liquid)

- ejector vapor pumps (vapor-liquid)

1.1 1.1 Ejector hydro pumps (liquid-liquid)

A liquid (most often water) is used as the driving fluid in these pumps. These pumps are widely applied in many fields: for small and large flows (from several l/h to several thousand m3/h), for low and high output pressures (from minimal to > 20 bar), for low and high temperatures, for pumping water from great depths (depths greater than 500 m), for pumping (drawing in) and thrusting liquid with mechanical admixtures of different sizes and origin (see ejector hydro-transport), for pumping (drawing-in) liquid that contain gases, for increasing pumping-in heights of other pumps, for preventing pump cavitation, for transport of warm liquids, for pumping-in and thrusting acid, alkaline and other chemical liquids, emulsions and suspensions with different concentrations and compositions, for performing chemical reactions and other special and individual applications.

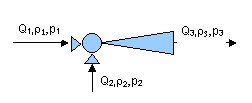

Q1, Q2 i Q3 – volume flow in (m3/s) or (m3/h),

r1, r2 i r3 – density in (kg/m3),

p1, p2, i p3 – pressure in (bar), recommended in (baraps)

Index 1 denotes the driving fluid entering the ejector, index 2 the drawn-in liquid at the ejector input and index 3 denotes a mixture of driving fluid and drawn-in liquid at the ejector output

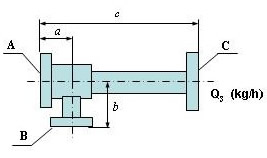

| Size | Max. flow Q3 (kg/h) |

Attachments DN |

Dimension (mm) |

||||

| A | B | C | a | b | c | ||

| 1 | 1200 | 20 | 20 | 20 | 40 | 80 | 150 |

| 2 | 3500 | 25 | 20 | 32 | 60 | 85 | 270 |

| 3 | 6000 | 32 | 25 | 40 | 65 | 100 | 350 |

| 4 | 12000 | 40 | 32 | 50 | 70 | 115 | 410 |

| 5 | 24000 | 50 | 40 | 65 | 80 | 125 | 480 |

| 6 | 32000 | 65 | 40 | 65 | 80 | 125 | 480 |

| 7 | 40000 | 65 | 50 | 80 | 80 | 125 | 530 |

| 8 | 70000 | 80 | 65 | 100 | 115 | 135 | 730 |

| 9 | 100000 | 100 | 80 | 125 | 150 | 165 | 950 |

Ejectors are produced with flanges, a threaded fastener and attachments for connecting with rubber or plastic tubes.

When ordering an ejector the following data needs to be given:

- density r1and r2 in (kg/m3),

- mass flow m1 and m2 or at least one of them in kg/s or kg/h or volume flow Q1 and Q2 or at least of them in m3/s or m3/h,

- of the three pressures p1, p2 and p3 two must be set (bar or barabs),

- if all three pressures are set than only one mass or volume flow can be set (see figure 1 and 1a).

Example 1.1

Data: The pumped water has a flow of m2=12.4 t/h, density r2=1.2 t/m3, pressure p2=1.2 barabs (the ejector is set 2 m below the level of the pumped liquid). The driving liquid has a flow of m1=20 t/h and density r1=1 t/m3. The pressure required at the ejector output p3=2.5 barabs. The pressure of the driving liquid p1 needs to be determined.

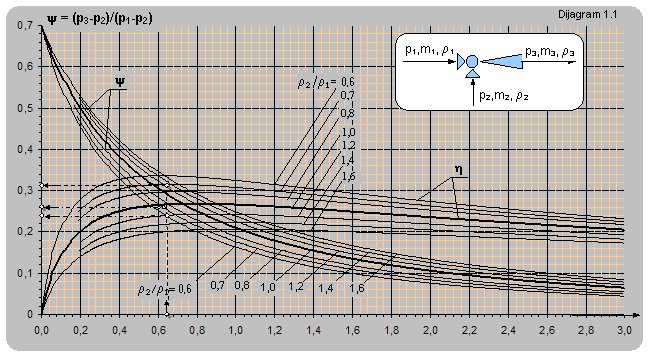

Solution: for m = m2/m1=12,4/20 = 0,62 and r2/r =1,2/1=1,2

From the diagram one can read y = 0,305 and h = 0,24.

p1 = p2 + (p3 – p2) / y =1,2 + (2,5 –1,2) / 0,31 = 5,4 baraps (4,4 bar)

Example 1.2

All data is the same as in example 1.1 only the ejector is placed 2 m above the pumped liquid level i.e. the pumped water pressure at the ejector input is p2=0.8 barabs (0.2 bar vacuum).

Solution: for m = 0,62; r2/r =1,2, and for y = 0,305 the required driving liquid pressure is

p1 = p2+ (p3 – p2) / y = 0,8 + (2,5 – 0,8) / 0,31 = 6,28 baraps (5,28 bar)

The utilization coefficient is the same as in example 1.1 h = 0,24.

|

| m = m2/m1(kgsunctioned liquid /kgdriving liquid) |

|

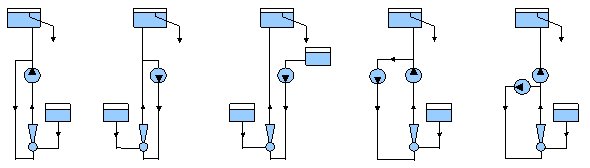

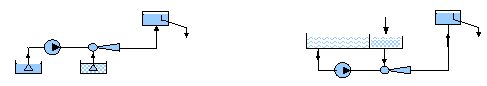

| Figure 1.2 Variants for pump and ejector connection |

|

| Figure 1.3 Ejector transport of dirty and muddy liquids |