EJECTOR PNEUMATIC TRANSPORT Division

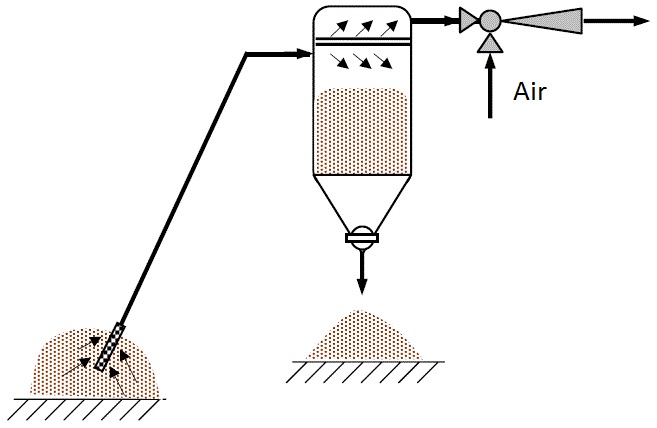

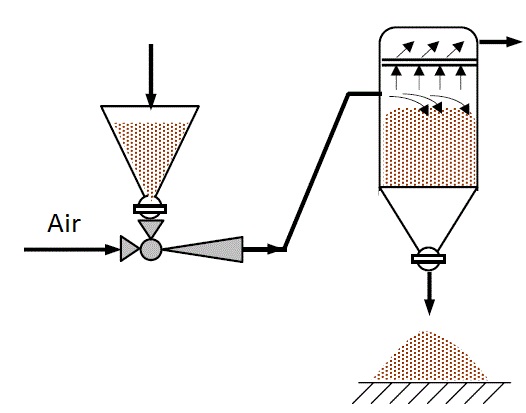

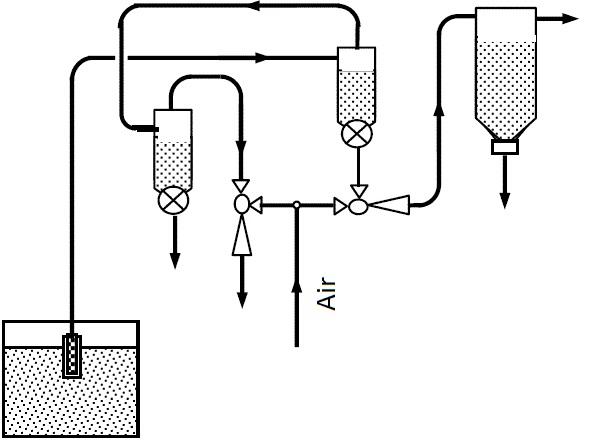

Pneumatic transport includes transport of powder and grain-like materials with air or another gas. Ejectors together with other devices are used for pneumatic transport. Besides transport of powder, grain-like and other loose materials ejector pneumatic transport can be used for liquid transport.

Taken in fluids of powder, grain-like or other loose materials can consists of a mixture of solid material and air or only solid material, with no air present. Also, if liquid is taken in then air can be taken in with the liquid or only pure liquid with no air present.

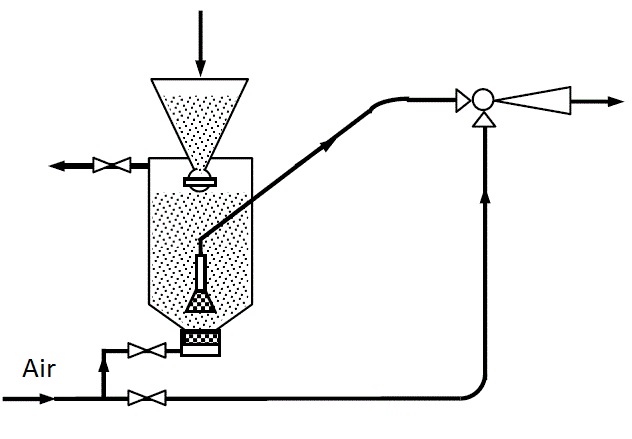

Loose material can be taken in using an intake or directly dosed into the intake chamber with a dosage device.

Transport of small and large amounts of loose material up to several tens of t/h is possible using ejector pneumatic transport. The ratio between the output and input pressure p3/p2 = 1,2-1,4 and using a special construction with selection of a corresponding transport system the output pressure can be several bars.

A combination of ejectors with a mammoth pump operating principle can lift large amounts of liquid to great heights.

Use:

They are used for the transport of powder, grain-like and all other loose materials. Transport can be performed as: intake, thrust or combined.

Liquid aeration is performed during pneumatic liquid transport

Advantages:

- ejectors have a simple construction;

- small dimensions and mass;

- have no mobile parts so do not require lubrication;

- are easy to manipulate and maintain;

- simple installation and they can be mounted in all positions;

- transported material does not stick to ejector walls;

- operation is stable, quite and noiseless;

- do not require electric energy nor driving engines;

- are cheep and have a long life.

Material:

They can be constructed from all types of sheet metals, metals, non-metals, plastic and other materials.

Data for ordering:

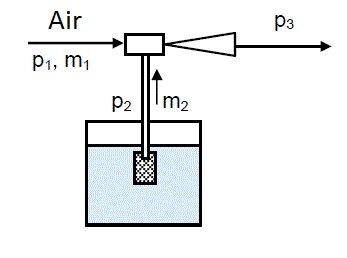

When ordering pressures p1, p2 and p3 or ejection coefficients should be given. Of the three pressures two need to be provided.

With m2t denotes the mass flow of the solid material taken in and m2g denotes the mass flow of secondary air in the material pumped in.

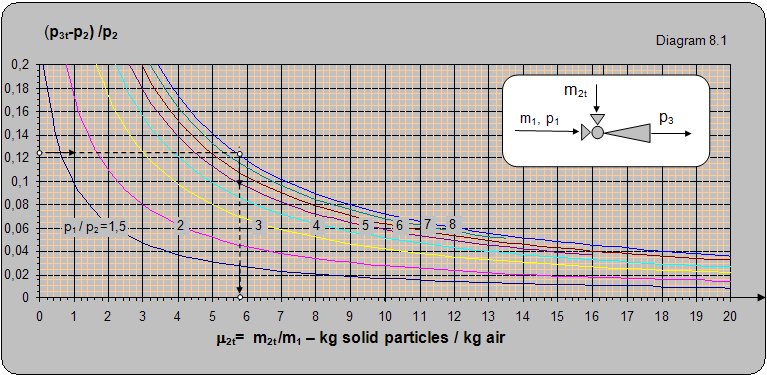

Example 8.1

Data: Pressure of compressed air at the ejector input p1 = 8 barabs, the pressure of pumped solid particle fluid is atmospheric p2 = 1 barabs and the pressure at the ejector output p3 = 0.125 bar (1.125 barabs).

Required: Injection coefficient mt = ?

mt = m2t/m1 represents the ratio between the pumped in solid particle mass (solid material with no air present) and the mass of the driving compressed air. The pumped fluid is a solid material when air is not present m2g= 0 i mg= m2g/m1= 0 (ratio between the pumped air mass and the mass of driving compressed air).

Solution: Za (p3-p2)/p2 = (1,125-1)/1 = 0,125 and ratio between the driving and pumped in pressure p1/p2 = 8/1 = 8, and using diagram 8.1 the coefficient is determined as mt =m2t/m1 = 5,8.

|

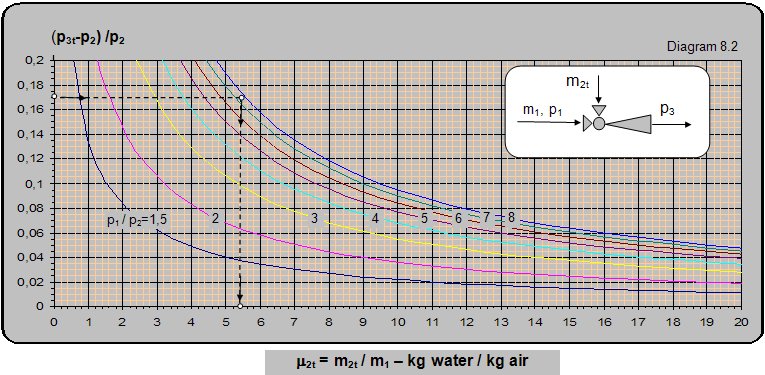

Example 8.2

Data: The pressure at the ejector entrance is p1 = 7 barabs (6 bar) and the pressure at the ejector output is p3 = 1.1 barabs (0.1 bar). The ejector is raised above water level for 0.6 m that corresponds to the water pressure at the ejector input of p2 = 0.94 barabs.

How many kilograms of water can be pumped with 1 kg of compressed air?

Solution: For the pressure ratio (p3-p2)/p2 = (1,1–0,94)/0,94 = 0,17 and pressure ratio p1/p2 = 7/0,94 = 7,45 using diagram 8.1 we read mt = m2t/m1 = 5,4. With 1 kg of air 5,4 kg of water can be pumped in.

|