EJECTOR HEAT PUMPS Division

According to their construction and operation method ejector heat pumps represent a specific type of heat pumps. Their construction is simple. They have no mobile parts. They do not use cooling fluids and use water vapor or cold water as driving fluids.

Using these pumps a large amount of heat energy present in waste water, vapor condensate and thermal underground waters can be utilized and returned into the process.

Operating principle:

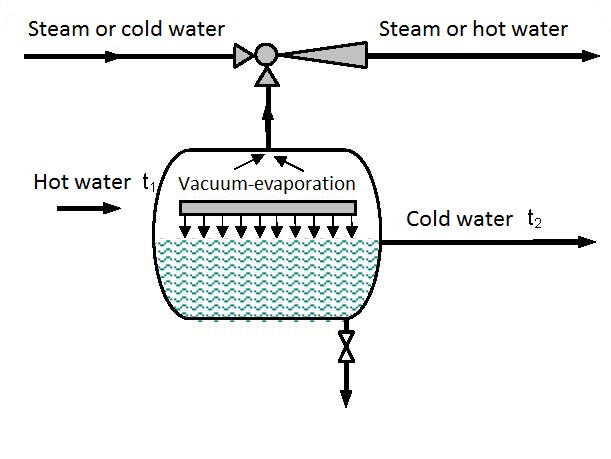

Warm liquid (most often water) with a temperature t1 is introduced into the evaporator (figure 9.1) where the absolute pressure is lower than the atmospheric one. Introduction of liquid into an area where the pressure is lower than the atmospheric one (vacuum area) boiling and evaporation of part of the introduced liquid occurs. The evaporated liquid takes the heat required for evaporation from the remaining liquid and thus cools it to temperature t2 (figure 9.1).

The temperature t2 of the remaining cooled liquid depends on the absolute pressure in the evaporator and is always in equilibrium with it. The evaporated water is pumped in via an ejector that uses fresh water vapor or cold water as the driving liquid, maintaining constant vacuum in the evaporator.

With a single step ejector an absolute pressure of p = 0.04 bar with a corresponding temperature t2 = 290oC can be attained in the evaporator, that means that the remaining part of the cooled water will leave the evaporator into the environment with a temperature of t2 = 290oC.

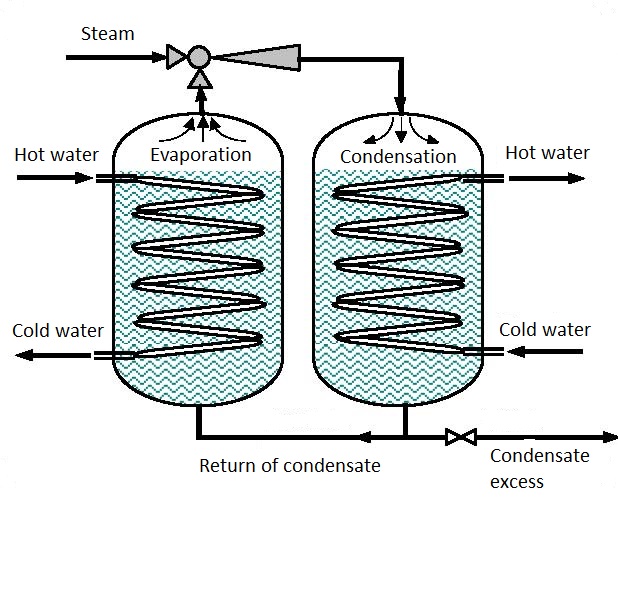

Mixing of pumped vapor with the driving vapor or cold water occurs in the ejector and part of the thrusting energy of the driving vapor (cold water) is delivered to the pumped vapor so the formed mixture exits the ejector under a corresponding pressure needed for further transport until the consumption point.

The amount of utilized heat energy depends on the input temperature of the excess warm liquid t1 and absolute pressure in the evaporator that is in equilibrium with the water temperature t2. If water is used as the driving fluid then all pumped vapor is condensed in the ejector and the condensation heat is delivered to the driving water that is thus heated.

Application

They are used for utilization of heat energy from all excess warm, clean and dirty liquids, underwater thermal water, water that is periodically released from heaters (desalinization and de-mudding), warm wetted dough-like and other materials.

Advantages

Ejector heat pumps have a series of advantages in relation to other similar devices:

- simple construction and small dimensions;

- can be used for low and high pressures;

- for small and large flows;

- for different temperatures;

- they do not have any mobile parts so do not require spare parts, maintenance and lubrication;

- have a stable, quiet and silent operation;

- do not require cooling fluids;

- do not pollute the environment;

- investments are small and the lifetime is practically unlimited;

- the whole process can be simply automated, so work control is minimized.

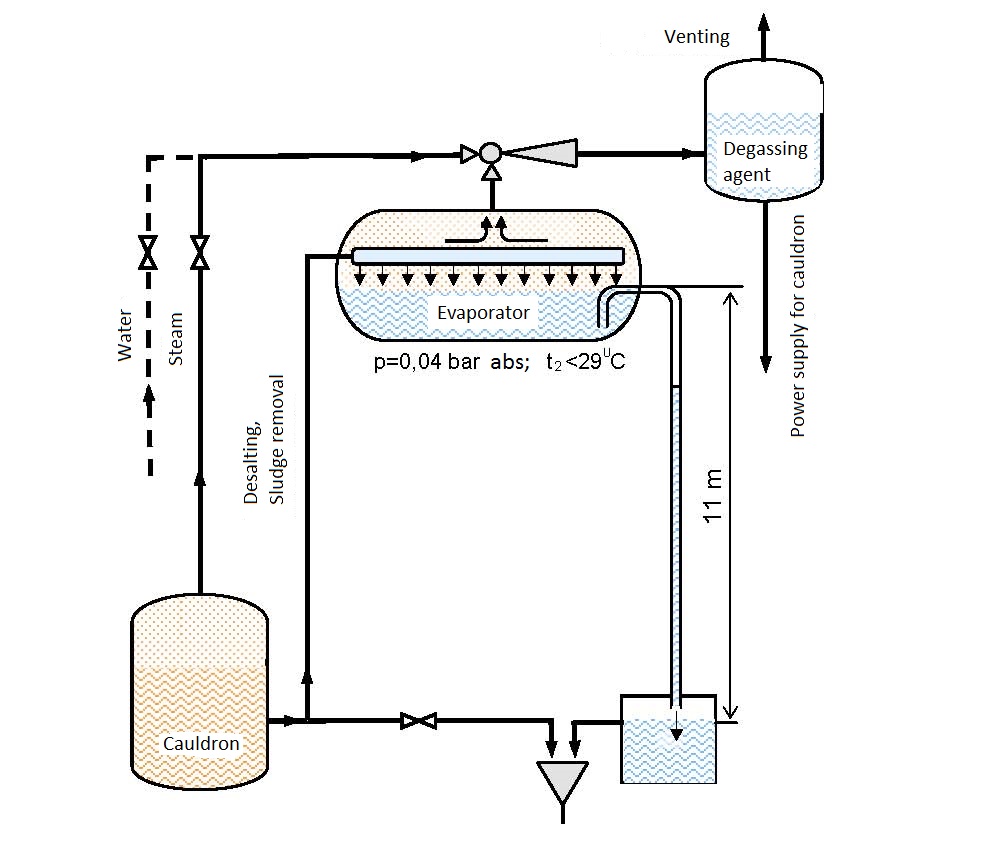

9.1 Utilization of heat energy from excess boiler water

An especially useful application of heat pumps is utilixation of heat energy from hot water that is occasionaly released from the boiler (desalinization and sludge removal). All boiler installations have degassers in which the feeding water is heated to the temperature of 102-105oC. Heating is performed using fresh boiler vapor that is reduced with a reducing valve to the pressure of 0.05-0.2 bar before enetering the degasser.

Vapor reduction from a high boiler pressure to the pressure of 0.05-0.2 bar destroys energy. If an ejector is installed instead of the reducing valve it will use the energy destroyed in the reducer to pump in vapor from the evaporator in time intervals when hot water is released from the boiler.

In the time intervals when water is not reduced from the boiler the ejector will work as a reducing valve. Installation of an ejector heat pump does not disrupt boiler safety measures as all output pipelines are open. The boiler workman performing sludge removal and desalinization will do his work regardless of whether the ejector is on or not.

If the ejector is on, in the time interval when water is released from the boiler, it will pump in part of the evaporated water, if it is not on, the released water via an evaporator and overflow vessel will exit. The collected heat from the evaporator is lead to a degasser or other consumer point.

Installation of a heat pump realizes the following savings:

- Savings in heat energy (that for example for boilers with a pressure of 10 bar, per 1 m3 of released water that cools in the evaporator from 460oC to 180oC is Q = (2776.3-2585.1)×103 = 221800 kJ = 53062 kcal that corresponds to 5-6 kg of crude oil,

- Savings in water (the evaporated pumped in part of used water is a pure destillate),

- It is a more ecological solution (lower environment pollution, the temperature of the released water is cca 290oC),

- Practically no energy is used as the energy used is what is destroyed in the reducing valve using the classical procedure.

|

| Figure 9.3 Heat pump – heat savings from excess boiler water |