EJECTOR VACUUM PUMPS Division

Ejector vacuum pumps are divided into:

- ejector vapor vacuum pumps (vapor – evaporate and gas);

- ejector hydro vacuum pumps (liquid – evaporate and gas);

- ejector gas vacuum pumps (compressed air – evaporate and gas).

Ejector vacuum pumps are widely applied in many fields where processes take place under pressures lower than the atmospheric pressure.

Pump capacity and vacuum height can be within wide limits (flows to several thousand m3/h and the pumped absolute pressure p = mbar). Ejector vacuum pumps for drive use energy of the driving fluid. Passing through the jet the driving fluid transforms most of its thrusting energy into kinetic (speed) energy so it enters the ejector mixing chamber at great speed (for gas and vapor at speeds above the speed of sound). In the mixing chamber the driving fluid comes into contact with the pumped fluid that it takes in, mixes and takes along compressing it to atmospheric pressure.

Application:

They are used for vacuuming vessels, devices and apparatus, increasing pumped heights of centrifugal pumps, pouring liquids and providing vacuum in many other operations.

|

|

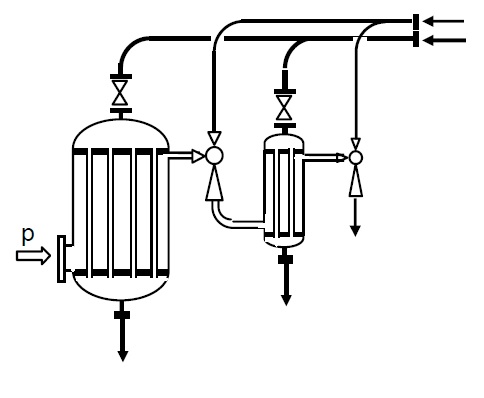

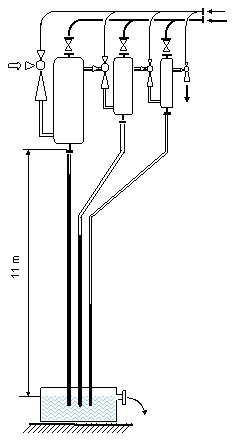

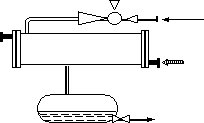

| Figure 10.1 Vacuuming in line | Figure 10.2 Recirculation vacuuming |

Advantages:

Compared to other types of vacuum pumps they have many advantages:

- no driving engines;

- their construction is simple;

- they have a small mass and dimensions;

- no mobile parts and parts that wear;

- do not require lubrication;

- are easy to maintain and handle, their operation is stable, quiet and noiseless;

- their installation is simple and they can be mounted in all positions;

- they are cheep and have a long lifetime.

10.1 Ejector vapor vacuum pumps

Water vapor is used to drive these pumps. They can be simple with one ejector (figure 10.2) or have several serially connected ejectors (figures 10.3-10.5). Simple ejector vacuum pumps are used for pumping pressures higher than 100 mbar of absolute pressure, and multiple ones are used for very low pumping pressures.

Ejectors can be connected directly or condensers are installed between them.

Condensers can be mixing (figure 10.3) in which a mixture of vapor and pumped gas is mixed with a cooling liquid or surface in which the output mixture of driving fluid and pumped evaporate are not mixed with the cooling liquid (figure 10.4). Depending on the way the condensate is conveyed they can be barometric (figure 10.5 – figure 10.6), semi-barometric and non-barometric. In barometric ejector pumps the condensate is lifted to a suitable height (depending on the vacuum height) in relation to the overflow vessel, while in semi-barometric or non-barometric vacuum pumps the condensate is evacuated with pumps or ejectors.

10.2 Ejector hydro vacuum pumps

Liquid is used to drive these pumps. The vacuum height in these pumps depends on the temperature and pressure of the driving liquid. Lower temperatures and higher pressures of the liquid achieve higher vacuum and vice versa. The lowest pressure that can be attained in a vacuuming area is equal to the pressure of the evaporation temperature of the driving liquid. The driving liquid can be used in one pass (figure 10.1) or it can re-circulate (figure 10.2). When working with re-circulated liquid, due to condensation of pumped evaporates, the driving liquid heats up so occasional or continual supply of fresh cold liquid is needed or ice can from time to time be introduced into the re-circulated liquid.

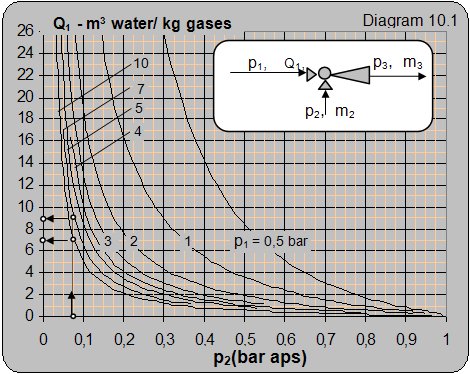

Diagram 10.1 is valid for the driving water temperature t1 = 150oC and atmospheric pressure at the ejector output (p3 = 1 barabs).

|

Example 10.1

Data: How many cubic meters of water need to be used per kilogram of pumped air if the absolute pressure of p2 = 75 mbar needs to be maintained in the vacuum vesse?

The driving pressure of water is known:

a) p1 = 10 bar

b) p1 = 7 bar

The water temperature is t1 = 150oC. The pressure at the ejector output is atmospheric.

Solution: According to diagram 10.1:

a) if water with a pressure of p1 = 10 bar (11 barabs) is used for drive for one kilogram of pumped air 7 m3 of water will be used;

b) if water with a pressure of p1 = 7 bar (8 barabs) is used for drive for one kilogram of pumped air 9 m3 of water will be used;

10.3 Ejector gas vacuum pumps

They most often use compressed gas (most often compressed air) for drive. These pumps are used for relatively low flows and low vacuum. They are most often used for providing suitable vacuum in pumping pipes of centrifugal pumps and for raising liquids from a lower to a higher level.

If these pumps are connected with classical vacuum pumps, with a water ring then air from the atmosphere is used as the driving fluid. Air from the atmosphere flows through the jet, where it accelerates and reaches the speed of sound at the output. If a Laval nozzle is installed then it reaches speeds above the speed of sound.

At this great speed air enters the mixing chamber in which it picks up the pumped fluid, takes it along and then compresses to pressures p>40 mbar and thrusts it into the water ring pump.