APPLICATION OF EJECTORS IN THE PRODUCTION OF DISTILLED WATER Division

From underground water in ejector installations.

Distilled water is obtained by destillation (heating by boiling, evaporation and condensation) from surface, water main or well water. There are no dissolved minerals or other admixtures in distilled water so as the chemically and mechanically purest water it is used in the food, pharmaceutical and many other chemical processes requiring clean water.

Large amounts of distilled water are used in the production of:

- alcoholic beverages,

- bear,

- antifreese,

- accumulators,

- and for filling steam boilers etc.

The simplest and most economical solution for obtaining distilled water is from thermal sources in ejector installations. Production of distilled water from underground hot water in an ejector installation represents a novel original solution, that for a small investment enables a large and cheep production. The installation capacity depends only on the temperature and amount of thermal water available.

Operating principle:

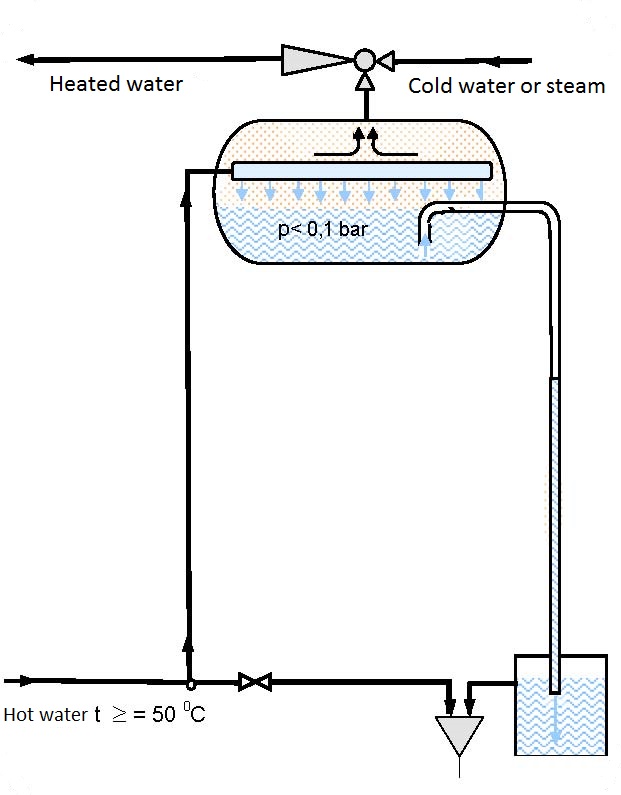

Warm water, from the spring, is brought via a pipeline to a vessel (evaporator). Introduction of hot water whose vapor strain (evaporation pressure) is higher than the absolute pressure in the vessel leads to sudden evaporation of part of the introduced water. The heat needed for evaporation is taken from the remining water thus cooling it until an equilibrium state is established between the temperature and pressure.

The evaporated water is puumped in and removed by the ejector, while part of the remaining cooled water is removed via an overflow into the surrounding area. The driving water when entering the ejector chamber comes into contact with the evaporated water from the evaporator, mixes with it, condenses it and takes it into storage reservoirs. The remaining part of water cooled to t< 400°C is removed from the evaporator via an overflow vessel into the environment.

Such an installation does not pollute the environment, but returns partially cooled water to the riverbed, i.e. returns water with a lower temperature that is an ecological improvement.

|

| Figure 13.1 Scheme of an installation for obtaining destillate from thermal underground waters |

Advantages in relation to existing processes

Production of distilled water from underground hot water using an ejectr installation has a series of advantages in relation to all other existing solutions:

- cheaper price per production unit,

- investment savings,

- savings in consumed heat and electric energy per production unit (thermal water does not need to be heated),

- maintenance savings (do not require lubrication),

- workforce savings,

- the installation is ecologically completelly clean and does not pollute the environment,

- production can be completely automated and performed 24 hours a day all year round.