EJECTOR AERATORS Division

Depending on the type of driving fluid aerators are divided into:

- ejector hydro aerators

- ejector gas aerators

In many technical fields (chemical, processing and food industry, mining and waterpower engineering) dirty and polluted water, containing undiluted solids of different origin and size, is removed from the production process. Waste water is most often a solution of gaseous liquid and solid waste materials and can be in the form of emulsions and suspensions.

Purification and treatment of waste water, among other procedures, uses the aeration procedure with an ejector aerator. Aeration in ejector aerators can be performed under different pressures and temperatures, with small and large flows (several hundred m3/h).

Besides waste water ejector aerators can treat: well, depth, spring and other waters containing dissolved minerals. Waters containing dissolved minerals are not tasty and are unsuitable for consumption. For this reason underground water, besides rare exceptions, must be, before use, treated and purified from dissolved compounds or iron and manganese. Increase of the amount of dissolved oxygen in water decreases the amount of dissolved iron and manganese.

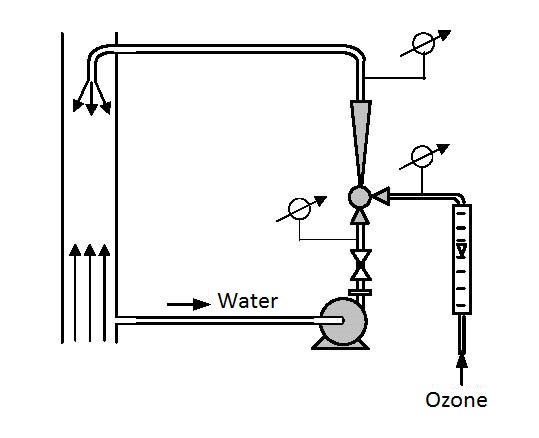

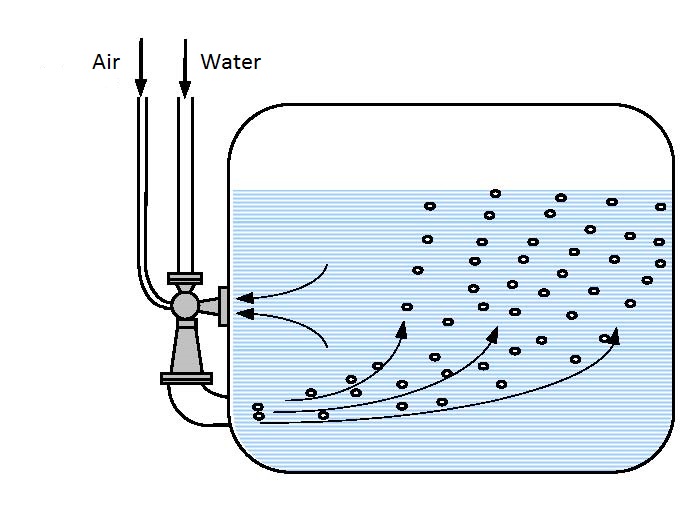

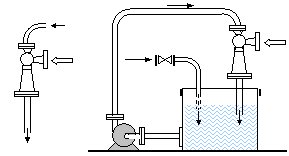

De-ferrization and de-manganization can be performed in objects on the surface of the earth and deep below. In objects on the surface oxidation can be performed in continual and clip circular processes. Continual aeration (figures 14.1)

|

| Figure 14.1 Actual aeration under pressure |

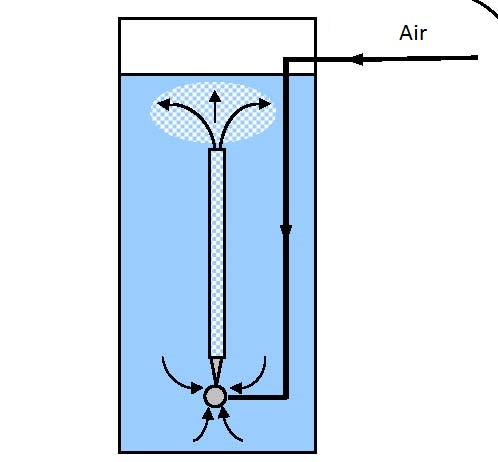

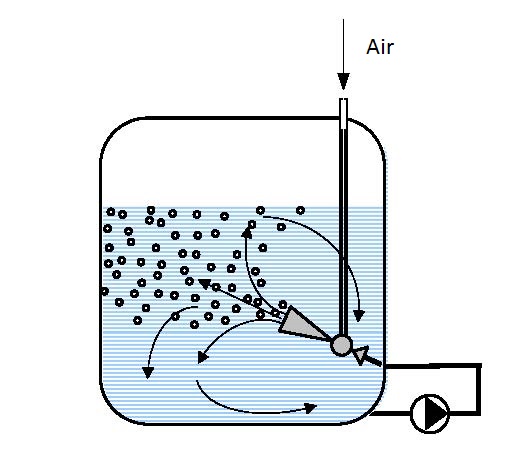

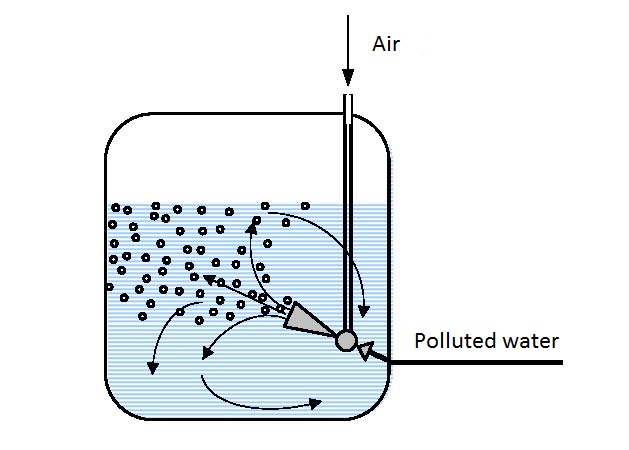

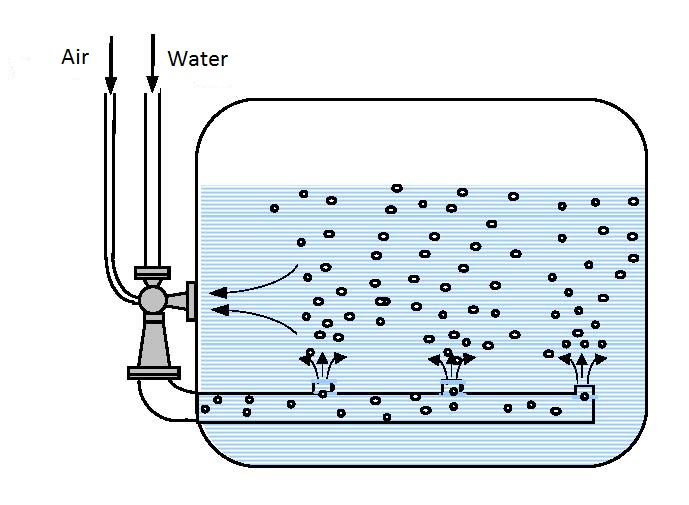

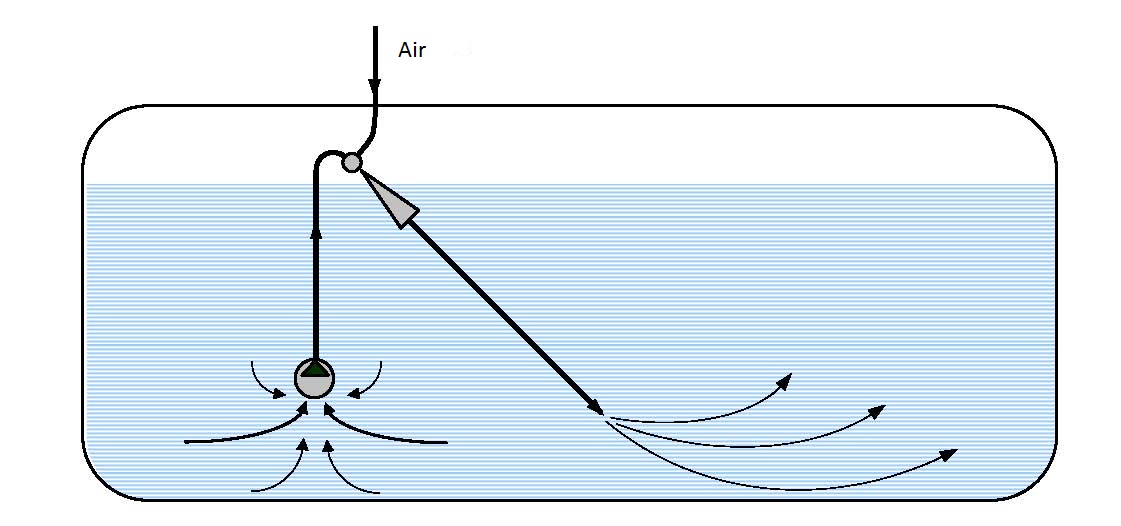

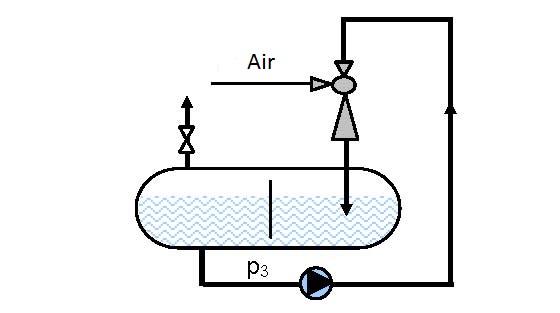

is performed with one or more serially connected ejectors. Clip aeration (figure 14.2 and 14.3) is performed by circular circulation processes. Underground aeration is performed by injecting water enriched with oxygen into underground water. Using ejector aerators ozone, pure oxygen, chlorine, and other gaseous and grain-like-powdery materials can be added that are used in water purification technology.

Ejector aerators operate on the same principle as other ejector devices. They use the energy of input fluid for operation (water or compressed air). The driving fluid (water or air) enters at great speed in to the ejector chamber where it collides and mixes with the pumped fluid (air or water). Due to different flow rates of the driving and pumped fluids both fluids break up into the smallest particles with large interacting surfaces. The large interacting surfaces lead to fast energy exchange and fast absorption and air (oxygen) solution. Dissolved oxygen reacts with iron and manganese making salts that settle and remain at the vessel or channel bottom. Ejector introduction of air performs blowing through of the polluted liquid that partially removes methane, ammonia and other gases.

|

|

| Figure 14.2 In line and recirculation aeration | |

|

|

| Figure 14.3 Circular-circulation aeration under pressure | |

Processes of gas solution in liquids can be divided into two groups: processes that require introduction of as much as possible gas (chlorination, ozoning, treatment of waste water etc.) and processes that require gas introduction until a saturated solution is reached (fishery and oil aeration).

Increase of the solution rate of oxygen can be attained by increasing the oxygen content in the pumped in air by moving air over zeolite filters etc.The gas solution rate in liquids depends on the mechanism of mass transfer between particles and gases. In an immobile environment molecular diffusion occurs very gently, so that complete solution saturation requires a long period of time. In a mobile environment the solution rate increases due to mass transfer in the mixture movement direction (convention) and turbulent flowing leads to the influence of pulsation causing turbulent diffusion.

Gas solution increases with the pressure increase and temperature decrease (see Ejector compressors and Ejector absorbers).

In continual processes liquid is moved over one or more serially installed ejectors.

In the clip procedure aeration is performed by circular-circulation movement through the ejector enabling complete saturation of the solution. Water from the aerator that contains part of the pumped in and un-dissolved air (oxygen) is ejected through perforated parallel or circulatory placed pipes. This method of distribution of the water-air mixture achieves more efficient mixing and faster saturation in the complete aeration space.

14.1 Ejector hydro-aerators

Water is used as the fluid in these aerators. They are used for flows up to several hundred m3/h for different temperatures and small and relatively high output pressures. The air/water volume ratio is within the 0-3 limits.

In fisheries ejector hydro-aerators can be used besides aeration for mixing deeper colder water with warmer surface water, antibiotic dosage, depth introduction of grain and powder food, depth dosing of limestone etc.

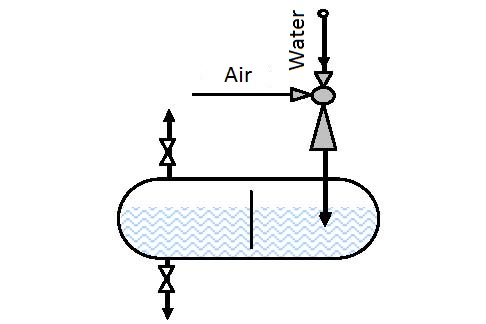

14.2 Ejector gas aerators

Gas aerators use compressed air for drive and polluted water as the pumped in fluid. These aerators are used when it is necessary to introduce relatively large amounts of air. They are used for small and large flows, different temperatures and not very high output pressures. More efficient mixing and faster saturation of the solution with oxygen can be attained using an ejector pneumo-hydraulic lift (figure 14.5).

|

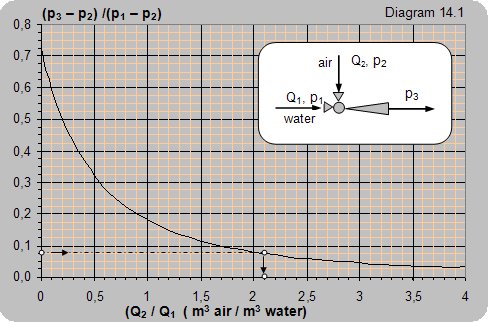

The diagram presents the dependence of the pressure difference on the flow volume ratio.

Example 14.1

Data: The water pressure at the ejector input is p1= 4 baraps (3 bar), the pressure at the ejector output is p3 = 1,24 baraps (0,24 bar). Air pumping is performed from the atmosphere p2 = 1 baraps.

How much air can be pumped in with one cubic meter of water?

Solution: (p3–p2)/(p1–p2) = (1,24–1)/(4–1) = 0,08.

From the diagram one can read Qvaz/ Qvode = 2,1. For the given conditions 1 m3 of water will pump in 2,1 m3 of air.